Low pressure dosing units

S dosing unit

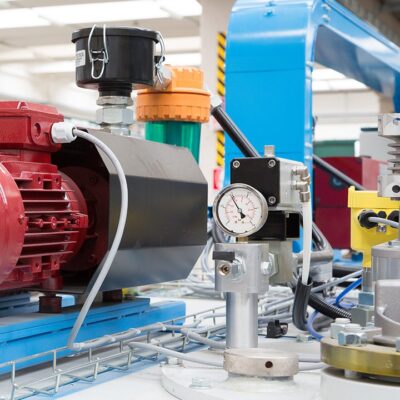

SAIP S low-pressure foaming machines are designed for mixing expanded and non-expanded polyurethane.

The S series is available with outputs ranging from 7 kg/min to 300 kg/min and component ratios from 1:5 to 5:1. The machines are powered by a PLC control and a Saip Touch Screen process control to set and display work parameters.

Production and ratio changes are powered by inverters with automatic component flow control.

The machine consists of:

- Storage and conditioning unit for isocyanates and polyols

- Isocyanate dispensing unit

- Solvent washing system of the mixing head

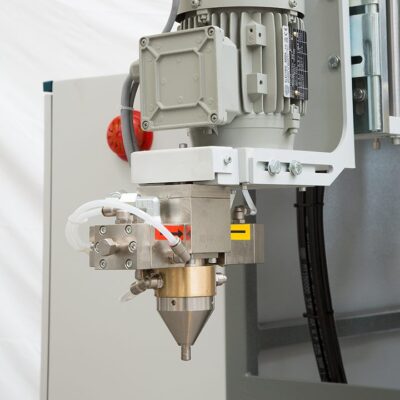

- Low pressure mixing head

- Mixing head support

- Control panel

Main accessories:

- Automatic tank loading

- Cooling unit

- Air circuit dryer

- Colour unit

- Air nucleation unit

- More adding programmes

- Tank stirrers

- Insulation of tanks and heat exchangers

- Mixer water cleaning system

- Suction filters at dosing pumps

- Silica gel filters

SD dosing unit

SAIP SD low pressure foaming machines are designed for special applications such as the production of dampers, industrial gaskets and filters, when the injection of micro quantities of polyurethane foam and a high level of precision are required by the application.

SAIP SD machines are high-performance dosing units, exported and appreciated all over the world.

The machine consists of:

- Storage and conditioning unit for isocyanates and polyols

- Stirrers on component storage tanks

- Isocyanate dispensing unit

- Water washing system

- Low pressure mixing head

- Sliding mixing head support

- Control panel

Main accessories:

- Electronic vibrating load levels

- Membrane loading pumps

- Mixing head pre-wash system with DOP

- Cooling unit

- Mass flow-meter

- Emulsifier

- Additional tank for high-density foam

- Magnetic coupling

Elastotech dosing unit

SAIP low-pressure dosing units for elastomers are designed and manufactured to dose and blend MDI prepolymer-based elastomers.

EL series machines are designed and developed to be easy to use, precise, reliable and robust.

Dosing systems for elastomers are suitable for any requirement and work environment.